Electric vehicles have seen remarkable advancements, and a crucial aspect of their performance revolves around the e-axle. High-speed e-axles offer significant benefits by enabling optimized torque production. These high-performance motors are designed to reduce energy consumption. The high rotational speeds achieved by these e-axles enable reduced weight, which ultimately improve the overall performance and efficiency of electric vehicles.

A key advantage of high-speed e-axles is their ability to produce significant power output. This makes them ideal in electric vehicles, as it allows for a smooth and responsive acceleration profile.

Furthermore, these systems also contribute to the reduction of noise and vibration, leading to a quieter and more comfortable ride.

Critical Shaft Fabrication for Optimal EV Drivetrain Performance

Electric vehicle (EV) drivetrains demand superior shaft design to achieve maximum power transfer. Precisely engineered shafts minimize energy loss, contributing to improved range and overall drivetrain performance. A variety of factors influence optimal shaft design, including component composition, coating technologies, and fabrication techniques. By carefully considering these elements, engineers can create shafts that enhance EV drivetrain efficiency and durability.

- Advanced shaft design practices often incorporate computer-aided modeling (CAD/CAM) tools to precisely predict performance characteristics under various operating conditions.

- Furthermore, rigorous testing and validation protocols ensure that EV shafts meet the stringent requirements of modern electric vehicles.

Ultimately, precision shaft design plays a essential role in achieving the optimal performance and reliability of EV drivetrains.

The demand for efficient electric vehicles is surging. This growth necessitates advancements in key components to maximize range and performance. High-precision shafts play a crucial role in achieving these goals, enabling seamless power transmission within the vehicle's drivetrain. By minimizing energy loss through inertia, these specialized shafts contribute significantly to overall power output.

Manufacturers are increasingly incorporating state-of-the-art manufacturing techniques to produce high-precision shafts with exceptional durability. This allows for tighter tolerances and smoother operation, ultimately leading to a more efficient electric vehicle.

Furthermore, Fine blank stamping the use of lightweight materials like titanium in shaft construction reduces overall vehicle weight, further enhancing energy density. The integration of high-precision shafts represents a significant step towards achieving the next generation of powerful electric vehicles.

E-Axle and Shaft Integration: A Key to EV Drive Train Reliability

The integration of e-axles and shafts within electric vehicle (EV) drive trains presents a fundamental aspect in ensuring overall system reliability. By seamlessly combining these components, manufacturers can minimize the risk of failures stemming from misalignment. This integrated design enhances power transmission, contributing to a smoother and more efficient driving experience. Furthermore, proper integration can maximize the lifespan of components, leading to reduced maintenance costs and overall system longevity.

Next-Generation Electric Vehicle Drivetrains: Advanced Shaft Solutions

Next generation electric vehicle drivetrains need innovative shaft solutions to optimize performance and efficiency. Advanced materials such as carbon fiber and titanium alloys are being incorporated into shaft designs to reduce weight while maintaining exceptional strength and durability. These lightweight shafts contribute to improved acceleration, range, and overall driving experience.

Furthermore, innovative manufacturing processes like additive manufacturing are enabling the creation of complex shaft geometries that maximize power transmission and minimize friction. This results in increased efficiency and reduced energy consumption for electric vehicles.

The development of advanced shaft solutions is crucial for pushing the boundaries of EV technology and achieving the full potential of electric mobility.

Transforming Automotive Engineering: E-Axle Innovations

The automotive sector is in a state of constant transformation, with engineers persistently pushing the boundaries of what's feasible. One of the most promising areas of innovation is the development of e-axles, which are altering the way vehicles perform. These sophisticated electric drivetrain systems offer a abundance of benefits, including improved fuel economy, reduced emissions, and an overall enhancement in the driving journey.

E-axles integrate all the primary components of an electric drivetrain, such as motors, gears, and controllers, into a compact and versatile unit. This centralized design simplifies the powertrain architecture, liberating valuable space within the vehicle structure.

Moreover, e-axles provide remarkable control over torque distribution, enabling vehicles to navigate with greater precision and stability. This enhanced agility is particularly beneficial in demanding driving conditions.

The adoption of e-axles is already gaining momentum across the automotive industry.

Major automakers are allocating heavily in research and development to develop innovative e-axle technologies, striving to create vehicles that are not only environmentally responsible but also remarkably performant. The future of automotive engineering is optimistic, and e-axles are poised to play a crucial role in shaping the next phase of mobility.

Jurnee Smollett Then & Now!

Jurnee Smollett Then & Now! Loni Anderson Then & Now!

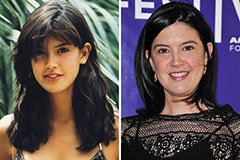

Loni Anderson Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Richard Dean Anderson Then & Now!

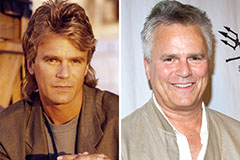

Richard Dean Anderson Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now!